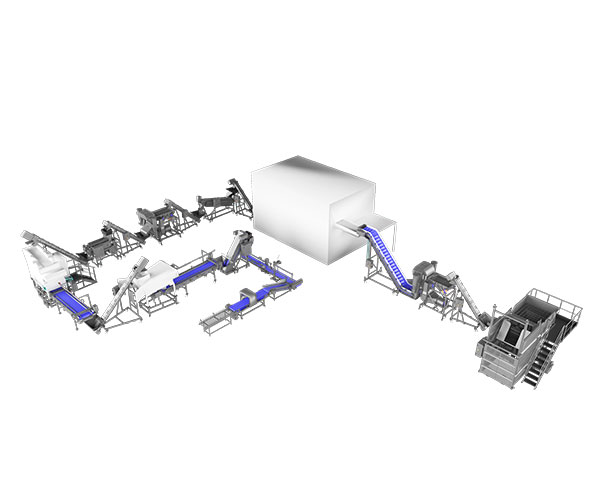

BERRY FRUIT LINE

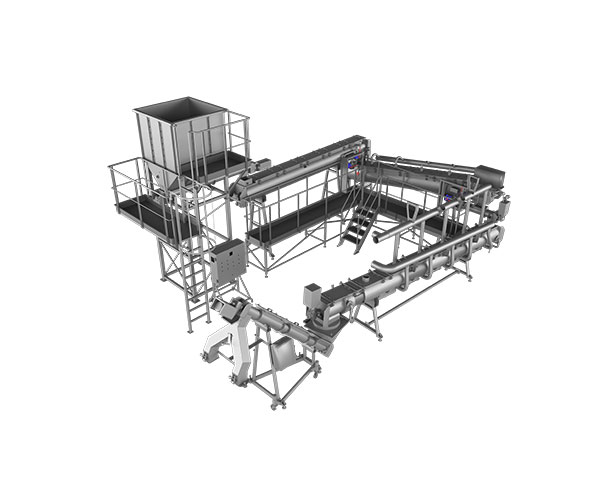

A modern line, tailored to the customer’s needs, enables the processing of frozen and fresh berries. It is equipped with a complete set of machines, thanks to which it can achieve high quality and efficiency.

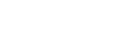

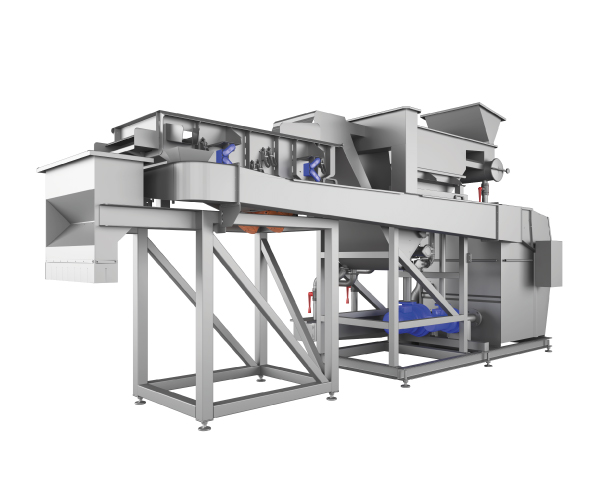

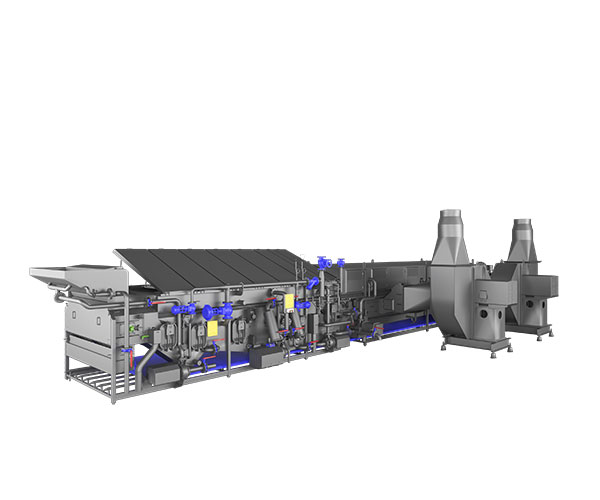

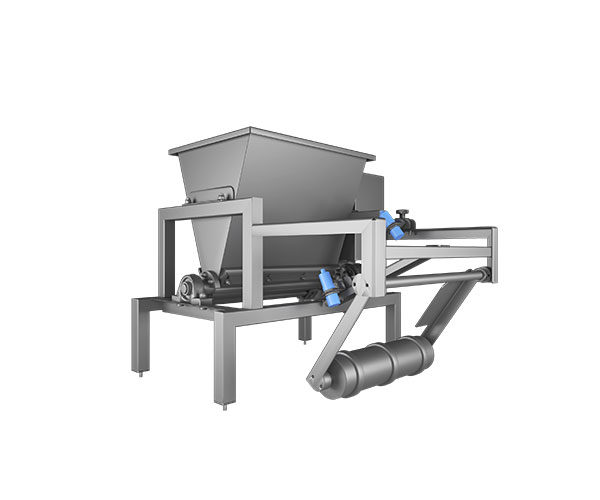

The berry fruits line consists of a high-lift tippler which pours the product into the hopper with a breaker inside. There, the product gets broken into the appropriate structure and evenly fed to the line. The fruit is transported by a vibratory feeder to the air cleaner, where the first stage of cleaning the impurities takes place.

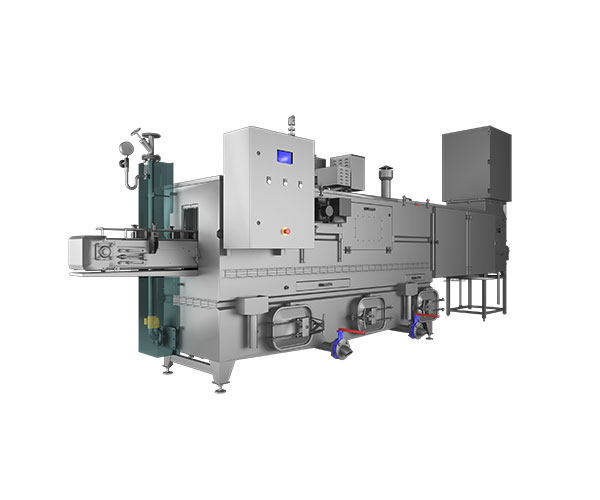

Then the fruits are transported to the vibrating screen. Thanks to the special design of the V-shaped channels and adjustable traps, the product of the desired size falls inside, and impurities such as twigs or stems are separated.

The next stage of production is the separation of stalks and the remnants of the inflorescences with the help of a stalk remover. Inside the machine, between the drum and the screw ribbon, friction is created, which makes the fruits rub against each other and cleans them.

The next stage is the berry polisher. With the help of brushes installed inside the drum, the device cleans the product of sticky stalks and inflorescences remains, and makes its surface nicely matted.

The final stage, depending on the customer’s needs, may be packing in collective or unit packages.

Detailed refinement of this line resulted in a carefully thought-out concept of the technological process and transparent operation of the devices. Thanks to the cooperation with our clients, we can learn more about their needs and create production lines that meet their requirements. Stainless steel machines, subjected to the right service, will remain operational for many years.