CHERRY LINE

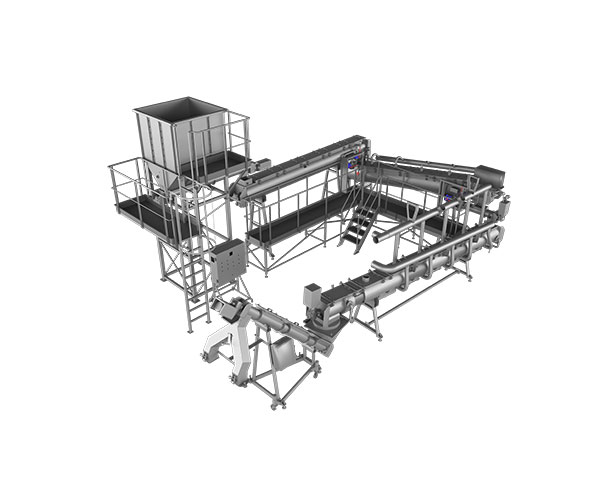

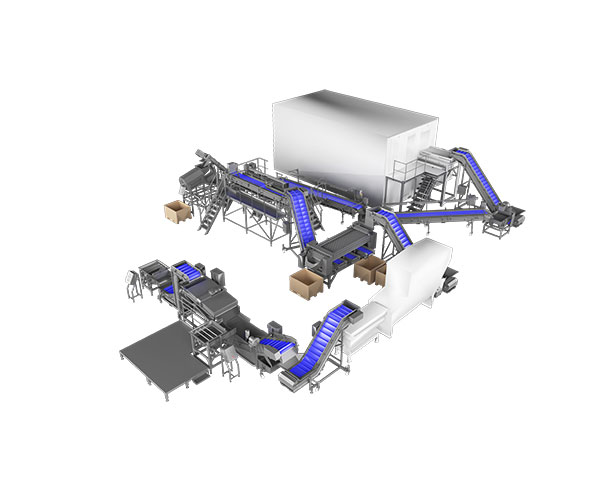

The line is intended for the preparation of cherries for freezing and the production of various types of jam and cherry preserves. It consists of multi-stage processes that include a section for destalking, washing, calibrating, pitting, manual inspection, dewatering and feeding to a freezing tunnel. The line is adapted to the processing of both hand-harvested and combine-harvested fruit. The system used in this line allows for the maximum recovery of semi-finished products such as juice, fruit flesh and seeds from cherries.

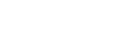

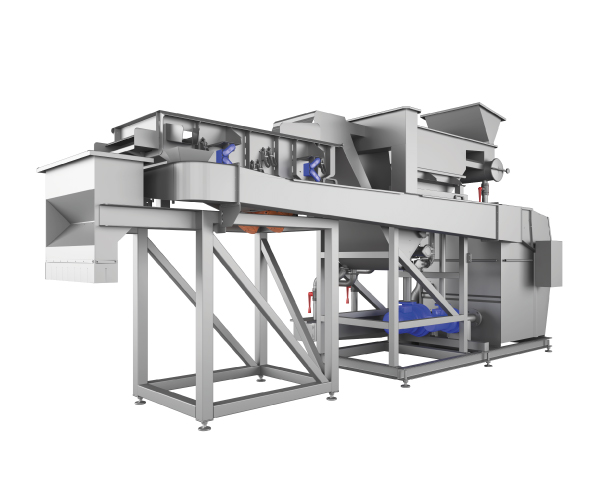

The process begins with a water-air washer, into which fruit is poured directly from boxes/containers. The washed fruit then travels via a conveyor to a vibrating screen, which allows the water and impurities to be partially separated from the product.

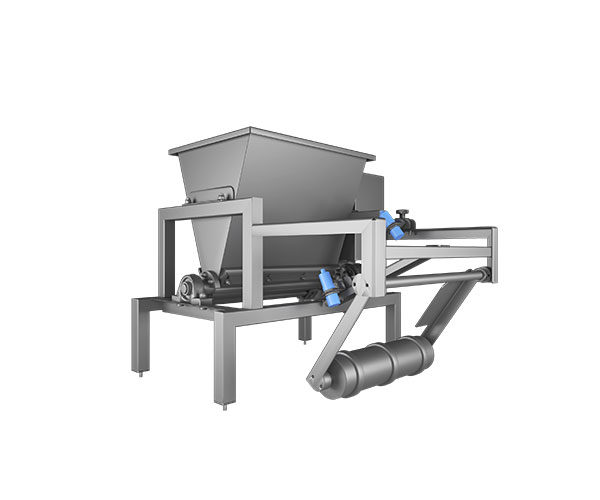

At the next stage, the fruit goes to the stalk remover which separates the stalk from the fruit by means of counter-rotating rollers, and pushes the cherry without a tail to the next stage, which is an inspection conveyor. At this stage, you can perform a visual quality and size inspection of the transported raw material.

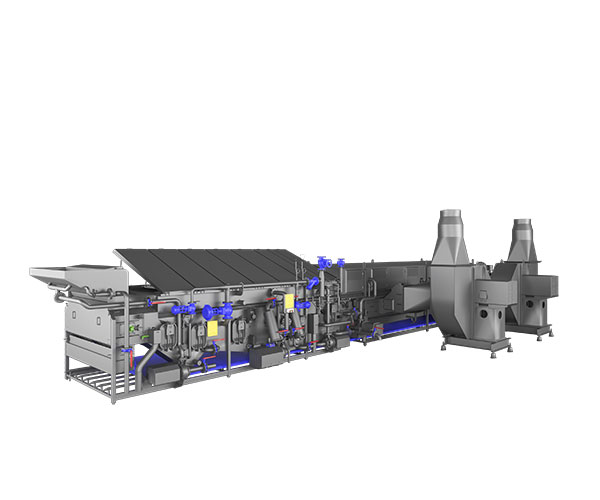

After that, it’s time to calibrate the cherries. The number of sorts and the size of calibrations can be selected according to the customer’s preferences. The cherry, divided into different sizes, goes to the pitting station. A common device chosen by customers for the cherry line is a fruit stone rubbing machine. With its help, you will separate the pulp from the seed and, as a result, you will get two additional semi-finished products that can be successfully used for other purposes.

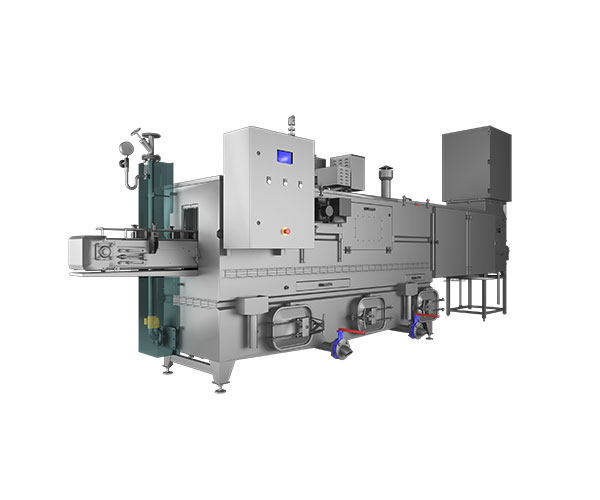

Right in front of the cooling tunnel there is a vibratory de-watering unit which, in the case of the cherry line, has the function of collecting the juice that is formed during processing. Thanks to that, you obtain another semi-finished product, i.e. cherry juice. The cherry, deprived of most of the juice, goes through the freezing process more efficiently, which translates into better performance of the cooling tunnel itself. After freezing, the cherry is transported by an inspection conveyor to the packing line.

Detailed refinement of this line resulted in a carefully thought-out concept of the technological process and transparent operation of the devices. Thanks to the cooperation with our clients, we can learn more about their needs and create production lines that meet their requirements. We can design all our machines according to individual customer requirements. Stainless steel machines, subjected to the right service, will remain operational for many years.