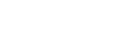

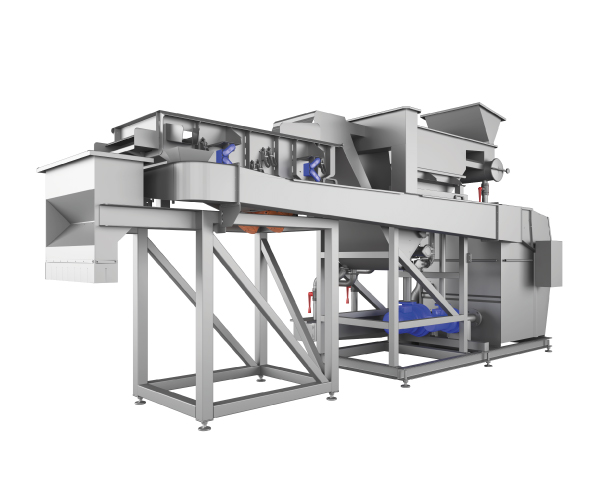

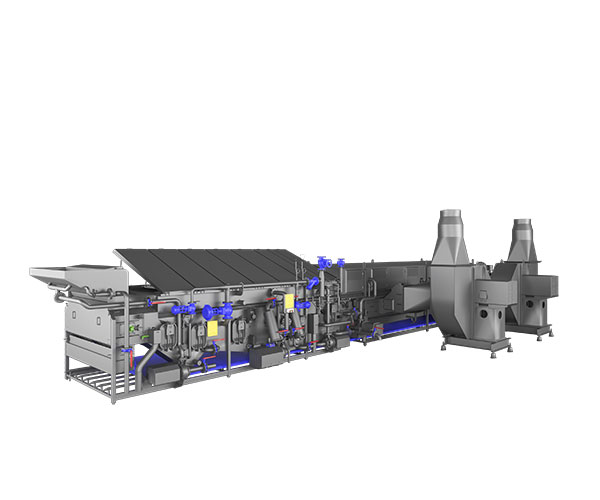

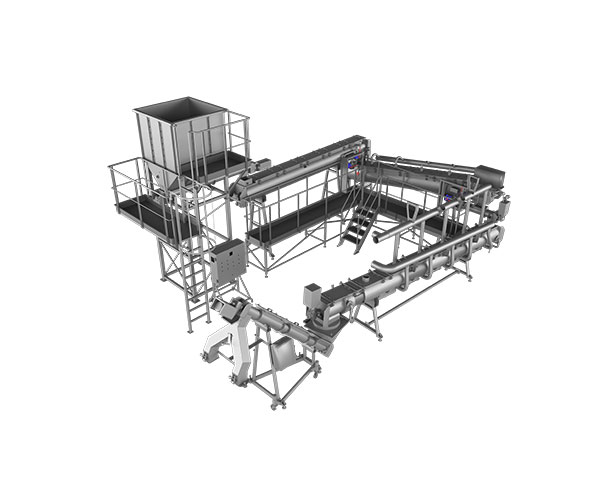

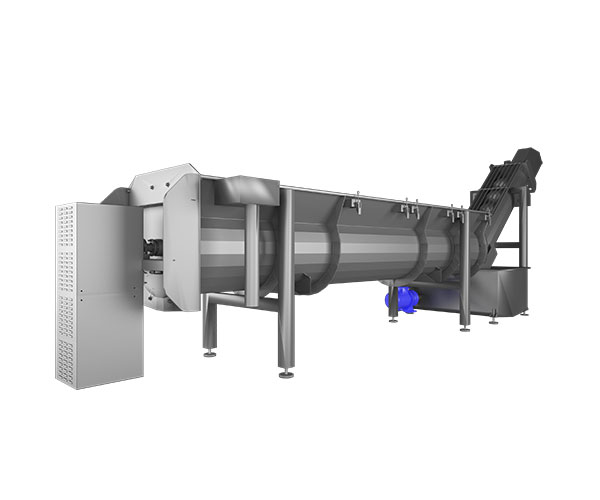

SCREW COOLER

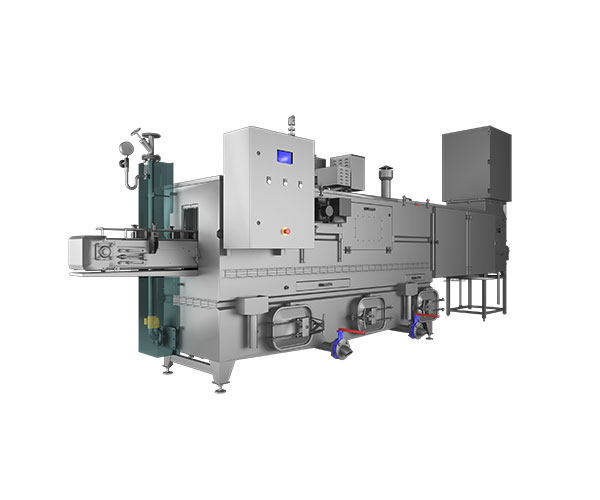

The device is used to cool the product in a water bath after the production process with high temperature (e.g. after blanching).

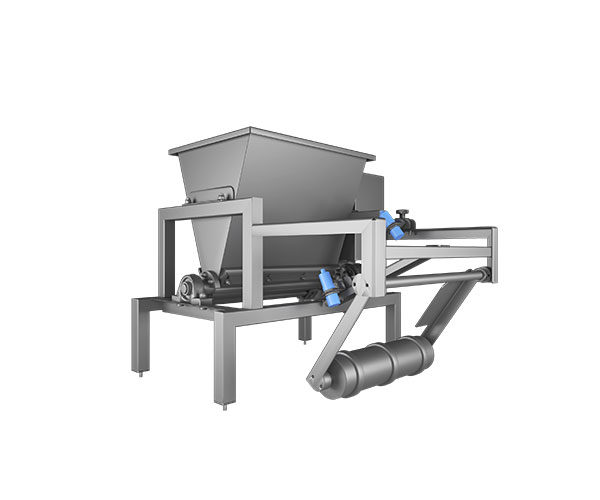

The raw material is fed to the device’s charging hopper, where it falls into the trough of the working screw. It is kept in a water bath for a preset time, which is ensured by the ribbon of the screw shaft creating chambers for the raw material. After passing through the entire length of the trough, the product flows onto the lifting screw conveyor, where it is simultaneously separated from the process water, and then fed to the next part of the line.

The automation and control unit allows you to select the optimal process parameters (water temperature, cooling time, etc.).

The construction of the device is solid and allows to maintain high production hygiene. It is also characterized by high ergonomics.

It is possible to equip the screw cooler with an additional machine, which is a water chiller, thanks to which it is possible to use chilled water continuously, while the addition of fresh water is limited to a minimum.