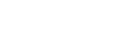

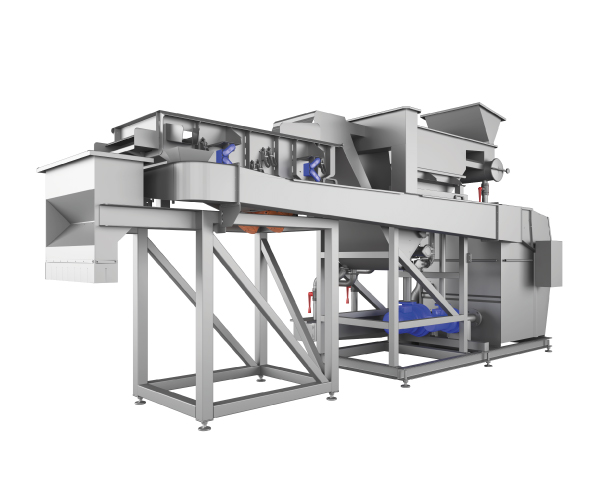

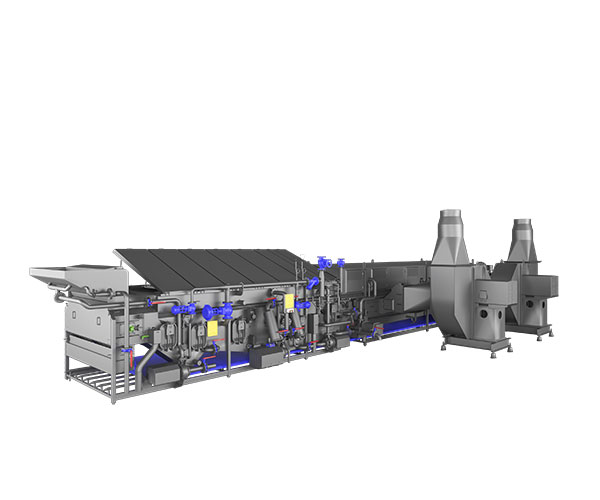

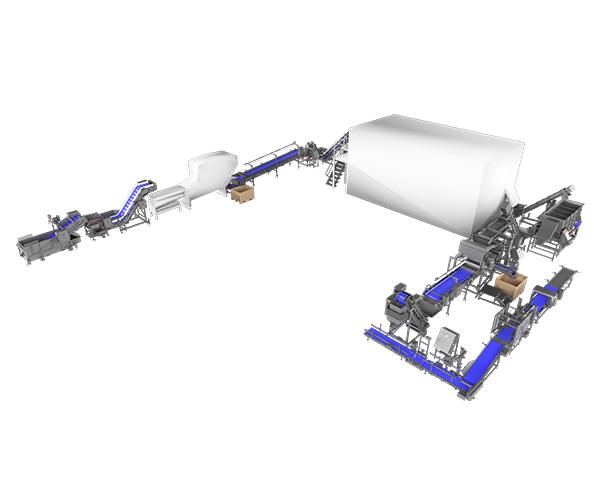

STRAWBERRY LINE

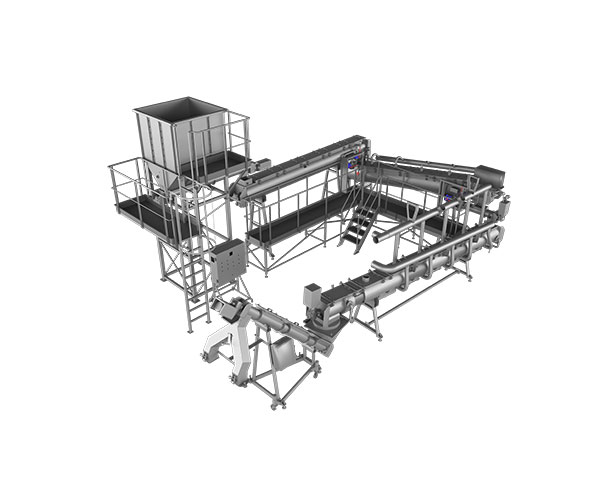

A line used for the processing of strawberries, tailored to individual customer needs.

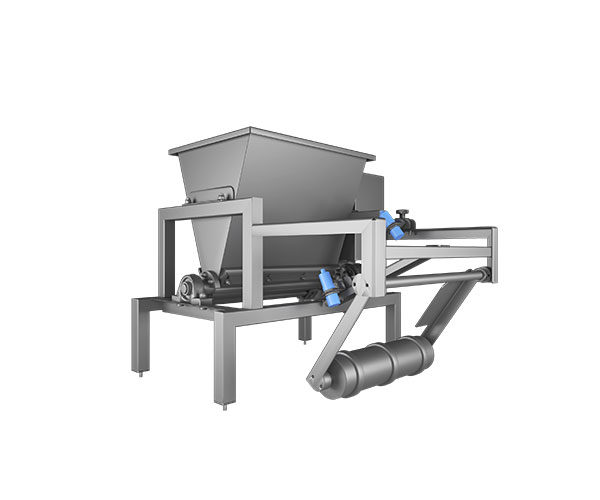

The process begins with throwing strawberries into a water-air washer. It minimizes water consumption thanks to the closed water cycle. The design of the washer allows for thorough cleaning of the product and, thanks to sedimentation, separation of the sand. The special cleaning system allows you to get rid of insects and floating debris. Thanks to that, contamination does not penetrate to the next stages of the line’s operation. It can be equipped with an immerse drum washer, which will effectively increase the level of washing in the case of a product with a high degree of dirt.

Then, the product goes to the brush washer and is rotated along it, getting thoroughly cleaned. The brushes remove all the remaining impurities that have penetrated with the product.

After this stage, the product is fed to a vibratory de-watering unit, which reduces excess water before freezing, thanks to which the product does not clump. By using this unit, you protect the work of the cooling tunnel, you do not subject it to the negative effects of a large amount of water which could cause freezing of some parts, and thus you eliminate downtime needed to defrost the machine.

The line is very universal, after the strawberry season it can be used for other fruits and vegetables such as currants, beans, peppers, onions, etc. – all floating.

Clients can also adapt the specifications of machines and lines to regional conditions in different world markets.

Process:

- Pre-washing

- Brush washing

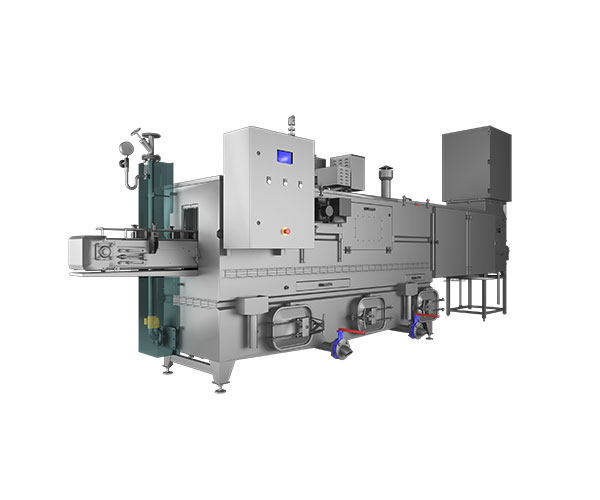

- Freezing

- Calibrating

- Weighing

- Packing

- Re-weighing

- Closing the cartons